Products

Commercial Electric Vehicles

Passenger & commercial electric vehicles such as buses, cars, and trucks have rapidly started replacing their IC engine-based counterparts owing to low energy costs, less noise, and high energy efficiency.

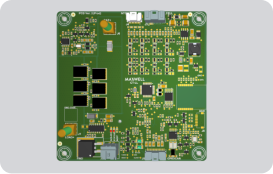

Products Designed for Every Application

Maxwell BMSs are designed to meet the different integration needs of the applications. Based on our vast experience of having integrated and deployed with similar applications, Maxwell BMS has unique features developed that allows for easy integration and better performance. For commercial vehicles :

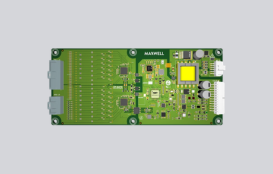

Distributed Master-Slave Architecture

Commercial vehicles have high voltage, high energy battery packs that have cells, distributed across several modules & sub-modules, connected in series and parallel. Distributed BMS architecture allows for the Slave BMSs to be connected close to the individual modules/submodules which inturn eases integration and simplifies wiring. These slaves are further interconnected and connected to the Master BMS through isolated wired communication interfaces.

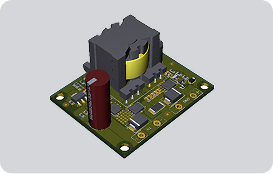

Feature Loaded

High voltage batteries ( > 60V) require adherence to several safety standards which in turn call for critical safety features to be present in the BMS. Maxwell BMS includes such features as High Voltage Interlock, Insulation Monitoring Device Interface, HV Measurement channels which can integrate with the vehicles at a system level and aid in meeting the safety goals.

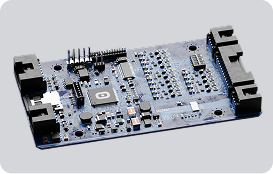

Compliant with industry standards

From basic configurability such as nominal current, cell chemistry, cell S&P layout to advanced configurability such as SOX tuning, configurable RDC, SOP, CAN, are readily supported on Maxwell BMS through an easily accessible application layer. With this application layer, lead time in tuning the BMS as per the vehicle’s needs is faster and simpler.

Trusted by global OEMs and battery pack manufacturers

As of 2021, Maxwell has become part of the Endurance Technologies Family. Endurance Technologies is one of leading auto component manufacturers, manufacturing in 3 countries from 27 plants and exporting to 28+ countries

Latest Insight

Maxwell gets accredited with ISO 9001:2015 Certification

Every job change decision involves a complex set of criteria and honestly, I firmly believe that leaving one company should not be the sole reason for joining another company.

A Layman’s Guide to Battery Swapping

Electric Vehicle adoption in India is set to rise exponentially over the course of the next 5-10 years, especially with honorary Finance Minister Nirmala Sitharaman announcing the government’s intent to

How Can Smart Charging Accelerate the Energy Transition?

The modern era vehicles aka Electric Vehicles (EVs), tend to solve one of the most intimidating problems of the present time – climate change.